Hydraulic pumps are used to generate fluid power in hydraulic systems, providing the force necessary to operate various components such as cylinders, motors, and valves. There are several types of hydraulic pumps, each with its own operating specifications.

Here is an overview of some of the most common types of hydraulic pumps and their operating specifications:

Gear pumps: Gear pumps are the most common type of hydraulic pump and are typically used in low-pressure applications. They consist of two gears that mesh together to create a vacuum that draws fluid into the pump and then pushes it out at a high pressure. Gear pumps are relatively simple and inexpensive, but they can be noisy and have limited efficiency.

Vane pumps: Vane pumps use a series of vanes that slide in and out of a rotor to create fluid flow. They are more efficient than gear pumps and can operate at higher pressures, making them suitable for a wider range of applications. Vane pumps are also quieter than gear pumps and have a longer lifespan.

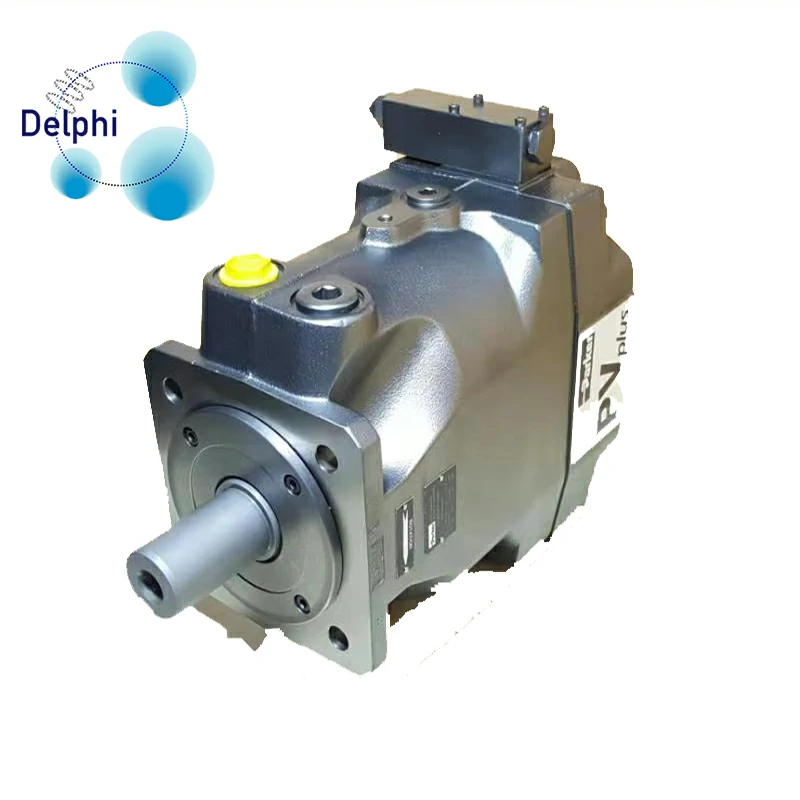

Piston pumps: Piston pumps use a series of pistons to draw fluid into the pump and then push it out at a high pressure. They are the most efficient type of hydraulic pump and can operate at very high pressures. Piston pumps are typically more expensive than gear or vane pumps but are suitable for high-pressure applications that require precise control.

Radial piston pumps: Radial piston pumps use a series of pistons that move radially to draw fluid into the pump and then push it out at a high pressure. They are similar to piston pumps but offer better efficiency and higher pressure capabilities. Radial piston pumps are typically used in high-pressure applications such as hydraulic presses and injection molding machines.

Axial piston pumps: Axial piston pumps use a series of pistons that move axially to draw fluid into the pump and then push it out at a high pressure. They are similar to radial piston pumps but offer better efficiency and higher flow rates. Axial piston pumps are typically used in high-pressure applications such as excavators and cranes.

In addition to the type of pump, there are several operating specifications to consider when selecting a hydraulic pump. These include flow rate, pressure rating, efficiency, and lifespan. It’s important to choose a hydraulic pump that is suitable for your specific application and can provide the necessary power and performance while minimizing energy consumption and maintenance requirements. Consulting with a qualified professional can help ensure that you select the right hydraulic pump for your needs.

What are some factors to consider when selecting a hydraulic pump?

When selecting a hydraulic pump, there are several factors to consider to ensure that the pump is suitable for your specific application.

Here are some key factors to consider:

Flow rate: The flow rate of the hydraulic pump should match the flow rate required by the hydraulic system. It’s important to ensure that the pump provides enough flow to meet the system’s requirements.

Pressure rating: The pressure rating of the hydraulic pump should match the maximum pressure required by the hydraulic system. It’s important to ensure that the pump can handle the maximum pressure without causing damage or failure.

Type of pump: There are several types of hydraulic pumps, including gear, vane, and piston pumps. The type of pump chosen will depend on the specific application requirements, such as the required flow rate and pressure.

Efficiency: The efficiency of the hydraulic pump should be considered, as a more efficient pump can reduce energy consumption and operating costs. hydraulic pump parts It’s important to choose a pump with a high efficiency rating.

Size and weight: The size and weight of the hydraulic pump should be considered, as a larger or heavier pump may not be suitable for certain applications or may require additional support.

Noise level: The noise level of the hydraulic pump should be considered, especially in applications where noise levels need to be kept to a minimum.

Maintenance requirements: The maintenance requirements of the hydraulic pump should be considered, including how often the pump needs to be serviced and the cost of replacement parts.

Compatibility: The compatibility of the hydraulic pump with other components in the hydraulic system should be considered, such as the valves, cylinders, and hoses.

Overall, when selecting a hydraulic pump, it’s important to consider the flow rate, pressure rating, type of pump, efficiency, size and weight, noise level, maintenance requirements, and compatibility with other components in the hydraulic system. Consulting with a qualified professional can help ensure that the right hydraulic pump is selected for your specific application.